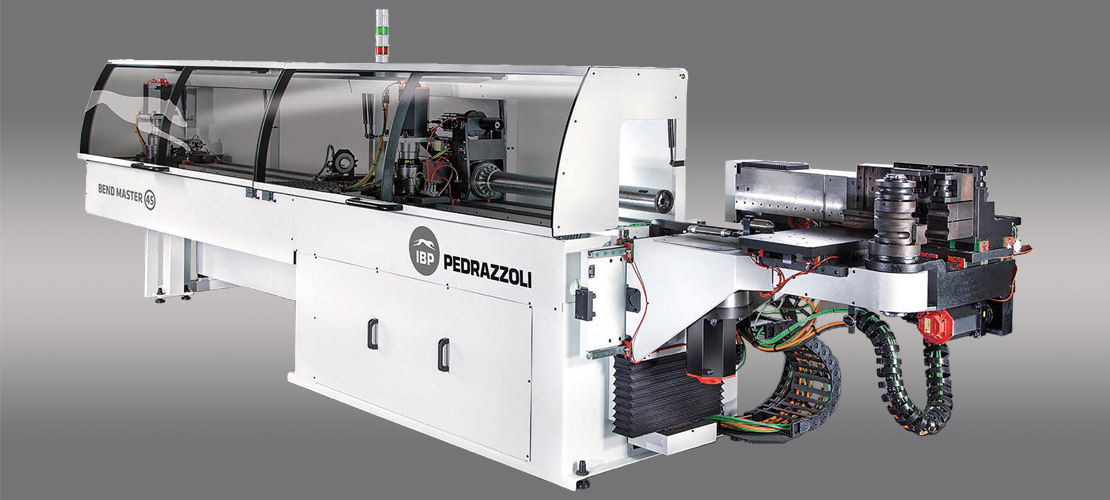

Unveiling the innovation of the Pedrazzoli Bend Master 45, where electric axis control seamlessly orchestrates both clockwise and counter-clockwise bending within a single cycle. Elevate your metal fabrication with the unique multi-stack tooling design, empowering the creation of bends with precision in fixed or variable radii. Crafted from the finest high-grade steel, the machine’s foundation guarantees enduring performance.

Every intricate part of the Bend Master 45 undergoes meticulous machining, adhering to exacting standards, with dimensions validated by state-of-the-art measuring systems. Experience flawlessly fluid linear guide movements, enhanced by re-circulating ball spheres, brushless motors, and an unwavering mechanical architecture. Immerse yourself in unparalleled accuracy, further amplified by the inclusion of a tool post strengthening tie rod.