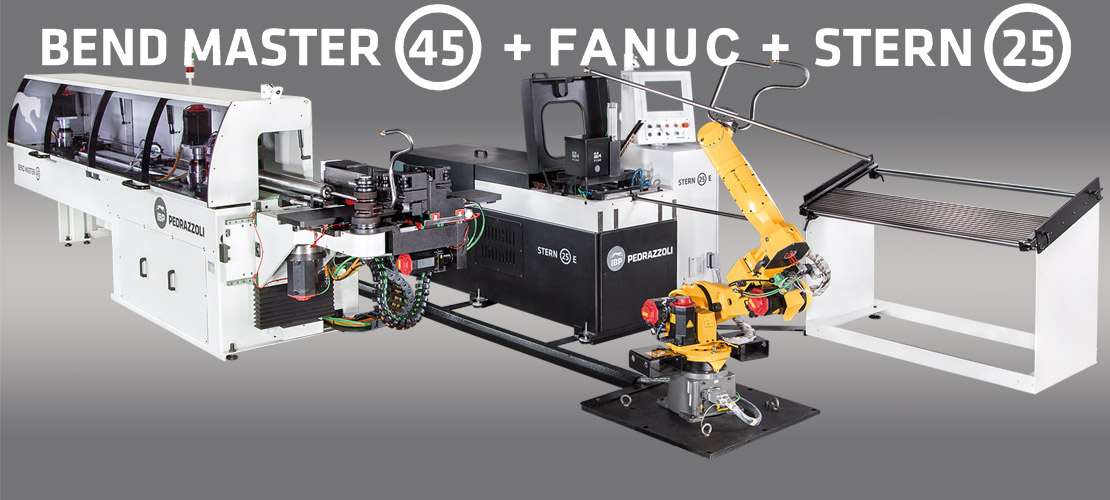

Automated Bending Work Cell

AUTOMATED BENDING WORK CELL

Imagine a cutting-edge work cell that revolutionizes metal fabrication through the seamless fusion of bending and end forming. This innovation is made possible by the incorporation of a highly advanced articulated loading robot. This robotic marvel meticulously replicates every intricate work phase typically carried out by a skilled human operator.

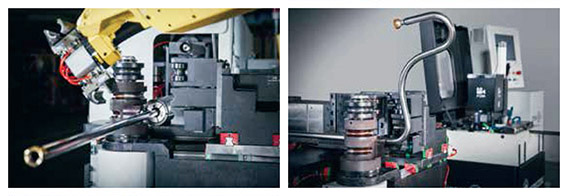

From material loading to precision bending and intricate end forming, this robotic assistant flawlessly executes each step of the process with unparalleled accuracy. The robot’s intricate articulations mirror the dexterity of a human hand, ensuring that every bend and end forming action is performed with meticulous precision.

Gone are the limitations of human fatigue and inconsistencies. This automated work cell introduces a new era of efficiency and perfection, where the harmony between robotic precision and human craftsmanship is seamlessly intertwined. The result is a symphony of ingenuity and productivity, setting the stage for the future of manufacturing.

KEY FEATURES

- Loading chute transfers tube towards the bending phase

- Single intervention of operator; adapt chute to tube length

- Automatic loader

- 10 electrically controlled axis for multi-radius and clockwise and counter-clockwise bends

- Automatic adjustment of tools for rapid set-up

- Maximum versatility in making various end forms

- Possibility of integrating phase for nut insertion onto bent tube

- FANUC robot; world leader in industrial robotics

- Double clamp for combined operations

- Integration of handling functions with quality control functions